Scaffolding Companies Wigginton

Top 10 Scaffolding Contractors in Wigginton

Receive up to 3 Scaffolding Solutions quotes for your project today! Compare profiles, reviews, accreditations, portfolio, etc... and choose the best deal.

ALPHA SCAFFOLDING & PLANT HIRE LTD

4.118 reviewsThe Yard Geldard Road Birstall WF17 9QD, The Yard Geldard Road Birstall, Birstall, WF179QD, GBYorkshire's Leading Scaffolding Experts, Alpha Scaff, are committed to providing professional scaffolding hire and sales services to commercial, industrial, domestic, and residential clients throughout Yorkshire. We pride ourselves on delivering scaffolding and scaffold to exceptionally high standards, with a unique customer focus on all our services. We supply and erect independently tied scaffold in both steel and aluminium, offering a multitude of solutions to suit your specific requirements. Our expertise spans a wide range of projects, including construction companies, local builders, authorities, NHS and schools, shopping centres, and conservation projects, heritage work, and mill conservations. We also provide emergency services for fire damage and demolition. Whether you're designing or building a project in Yorkshire, Alpha Scaff can help! We offer a free onsite survey with an independent quotation, with no obligation.

- Services

- Why Us?

- Accreditations

- Testimonials

- Gallery

Get Quote

MD Scaffolding Solutions Ltd

4.69 reviewsBarnsley, GBExpert scaffolders serving Yorkshire & surrounding areas. We provide a fast reliable competitive scaffolding build, hire service for the construction & industrial sectors. Our area coverage is nationwide. Based in Barnsley, South Yorkshire, we are driven by the quality of our work, and this is the reason our portfolio of clients is increasing by the day. All our workforce holds certified Construction Industry Scaffolders Record Scheme (CISRS) Cards and ranges from Advanced Scaffolders to Basic Scaffolders and Labourers. We believe that all aspects of Construction Design Management Regulations 2015 and Work at Height Regulations 2005 are catered for all our clients and offer bespoke solutions where required giving you peace of mind that you hired the right professional fully insured team. We provide our own in-house inspection service, and we also recommend using independent 3rd party inspection companies to verify our works. We can now share our excellent news that we have achieved the CHAS standard. This is Safety Schemes In Procurement (SSIP) awarding body which is UK Gov recognised for reaching the requirements as a Safe and Professional Contractor. We have our own External Health and Safety Consultants from ScaffSafe Ltd who ensures we are legal and compliant. ScaffSafe is a full information member of the National Access Scaffolding Confederation. We feel their knowledge and expertise have been crucial in our operations with their constant support where nothing is ever an issue to them. They were also pivotal in assisting us to gain our UK Gov CHAS Membership and issue us professional mentoring and have helped us expand the business and win exclusive contracts. We highly recommend them to others as their service has been outstanding. Click the logo below to find out more. Get in touch RESIDENTIAL COMMERCIAL INDUSTRIAL Why choose MD Scaffolding Solutions? Reliable, competitive & professional Over 20 years experience CITB registered All work guaranteed We provide scaffolding for a range of applications Chimney Stacks Edge Protections Event Stages School Works Heritage Scaffolding including Churches New Build Development Residential Extensions Roof Scaffolding Gantries Support Structures Staircases Street Works Scaffolding Industrial Scaffolding Bespoke Scaffold Access Design/Complex Scaffolding What our customers are saying “Top company.. highly recommended would recommend to all” Stephen Baxter “Absolutely fantastic company. Customer service outstanding, a pleasure to have work for us.” Richard Miller “Top lads, very satisfie

- Services

- Why Us?

- Accreditations

- Testimonials

- Gallery

Get Quote

Eyre Scaffolding (Yorkshire) Ltd

55 reviewsYork, GBEyre Scaffolding is a family-run business established in 2013. We provide a comprehensive scaffolding service, encompassing both hire and erection, to residential, commercial, building, and construction industries. Our services cater to a wide range of projects, from small access towers to large-scale construction works. We pride ourselves on offering design facilities and calculation drawings to ensure precise and safe scaffolding solutions. Our commitment to customer satisfaction is reflected in our repeat business, a testament to our consistently high standards of safety, quality, and service. We strive to exceed customer expectations by providing a personalized and reliable service, understanding our role as a vital link in our clients' supply chain. We prioritize getting it "Right first Time" and are dedicated to meeting and exceeding the latest health and safety legislation.

- Services

- Why Us?

- Accreditations

- Testimonials

- Gallery

Get Quote

CSP Scaffolding - Grimsby Scaffolding

2 Celandine Court, Grimsby, DN41 7JG, GBCSP Scaffolding Ltd. is one of the leading companies in the Lincolnshire area. Safety is our top priority. With over 30 years’ experience in the industry, we have a wealth of expertise in domestic, commercial and industrial scaffolding. We believe that “we are as good as our last job”. We have a strong focus on delivering quality services, within a timely manner, at an affordable rate. All our scaffolders and inspectors work to TG20:21 guidelines, we are CITB (Construction Industry Training Board) and CIRIS (Construction Industry Scaffolders Record Scheme) certified and comply to working at heights regulations 2005. For a free no obligation quote, please get in touch.

- Services

- Why Us?

- Accreditations

- Gallery

Get Quote

Calder Scaffolding Ltd

Unit 2.20 Holmfield Business Centre, Holdsworth Rd, Halifax, HX3 6SN, GBCalder Scaffolding Ltd is a trusted company with 15 years of trading history, run by management with over 40 years of experience. Established in 2005, we serve West Yorkshire and surrounding areas, including Greater Manchester. We specialize in catering to the scaffolding needs of commercial, residential, and industrial clients. Our goal is to provide quality on-time projects and offer the best service in the industry. We are fully insured with £10 million pound liability insurance, ensuring your property is in safe hands.

- Services

- Why Us?

- Gallery

Get Quote

Gap Scaffolding Services Ltd

32 reviews11 Peel Place, Barnsley, S71 1LU, GBGAP Scaffolding Services was formed in 2003, utilizing Steven Griffith's (Director) previous knowledge and skill set in Scaffolding and Health & Safety Management. Over the years, the director has developed a highly skilled management team, and the company now offers expertise in various areas. Projects are managed to a high professional standard due to a structured approach and experienced management. GAP Scaffolding is selective in its workforce, employing only the best fully qualified CISRS tradesmen with extensive knowledge in their respective trades. The company provides a complete scaffolding service through strong alliances with architects, surveyors, and structural engineers. GAP Scaffolding's experienced team supplies and erects a complete range of scaffolding systems. They pride themselves on their fast, efficient, courteous, and presentable service at competitive prices for both domestic and commercial building projects.

- Services

- Why Us?

- Gallery

Get Quote

Yorscaff Scaffolding Ltd

510 reviewsYork, GBYork's Leading Scaffolding Erectors Yorscaff offer a professional and reliable scaffolding service throughout York and the surrounding areas. We are a family run business with over 20 years experience in the scaffolding industry. We pride ourselves on our high quality workmanship and competitive prices. We are fully insured and all our employees are CISRS registered. We offer a wide range of scaffolding services, including domestic, commercial and industrial scaffolding. We also offer a 24 hour emergency service.

- Services

- Why Us?

- Our Team

- Testimonials

- Gallery

Get Quote

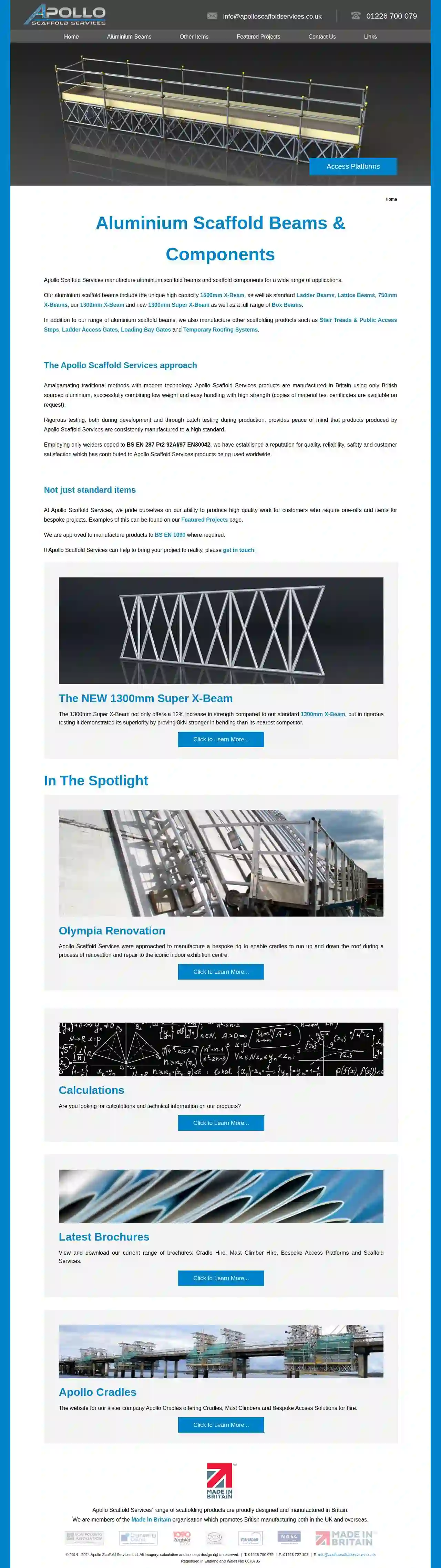

Apollo Scaffold Services Ltd.

York, GBApollo Scaffold Services manufacture aluminium scaffold beams and scaffold components for a wide range of applications. Our aluminium scaffold beams include the unique high capacity 1500mm X-Beam, as well as standard Ladder Beams, Lattice Beams, 750mm X-Beams, our 1300mm X-Beam and new 1300mm Super X-Beam as well as a full range of Box Beams. In addition to our range of aluminium scaffold beams, we also manufacture other scaffolding products such as Stair Treads & Public Access Steps, Ladder Access Gates, Loading Bay Gates and Temporary Roofing Systems. The Apollo Scaffold Services approach Amalgamating traditional methods with modern technology, Apollo Scaffold Services products are manufactured in Britain using only British sourced aluminium, successfully combining low weight and easy handling with high strength (copies of material test certificates are available on request). Rigorous testing, both during development and through batch testing during production, provides peace of mind that products produced by Apollo Scaffold Services are consistently manufactured to a high standard. Employing only welders coded to BS EN 287 Pt2 92AI/97 EN30042, we have established a reputation for quality, reliability, safety and customer satisfaction which has contributed to Apollo Scaffold Services products being used worldwide. Not just standard items At Apollo Scaffold Services, we pride ourselves on our ability to produce high quality work for customers who require one-offs and items for bespoke projects. Examples of this can be found on our Featured Projects page. We are approved to manufacture products to BS EN 1090 where required. If Apollo Scaffold Services can help to bring your project to reality, please get in touch. The NEW 1300mm Super X-Beam The 1300mm Super X-Beam not only offers a 12% increase in strength compared to our standard 1300mm X-Beam, but in rigorous testing it demonstrated its superiority by proving 8kN stronger in bending than its nearest competitor. Click to Learn More... In The Spotlight River Severn Eel Screen Installation In an industry first, Apollo Scaffold Services’ Lattice Beams were used to undert

- Services

- Why Us?

- Gallery

Get Quote

Blade Scaffolding Ltd

511 reviewsUnit 14, Cityway Trade Park, Bradford, BD4 7NU, GBBLADE SCAFFOLD is a well-established family-run scaffolding company based in Bradford, known for its excellent reputation and client base. We pride ourselves on providing fast response times and a team of fully trained and highly competent scaffold erectors who adhere to all current health and safety standards. Our team undergoes the latest H.S.E tests and examinations, ensuring the highest level of safety on every project. We are committed to serving as your reliable partner in business, offering friendly, attentive, and professional service. Health and safety is of paramount importance to us. We take every measure to reduce and mitigate risks throughout the entire scaffolding process. From the initial design stage, we conduct detailed risk assessments, covering every aspect of the project from start to finish. Our erection teams are fully compliant with the latest health and safety legislation, operating under a strict policy that includes checks for firm and level foundations, time planning to avoid construction during busy periods, avoidance of power lines, the use of British Standards equipment, safety barriers at all heights, careful incorporation of ladders and lifts, all necessary tie-offs and supports, and weekly checks on the structure.

- Services

- Why Us?

- Accreditations

- Gallery

Get Quote

Bostock Scaffolding Access

Manby, Louth, The Old Grain Store, LN11 8EB, GBWhen you are in need of a scaffolder in , make Bostock Scaffolding Services your first port of call today. Whether you want to know more about what we can offer you, or want to discover more about our competitive prices, give us a call today. Since being established, the business has grown from strength to strength, ensuring a prompt and professional service, hence, we have developed an outstanding reputation within the local community. Our aim is to keep our services high and our prices very competitive.

- Services

- Why Us?

- Testimonials

- Gallery

Get Quote

Over 4,131+ Scaffolding Businesses registered

Our scaffolding companies operate in Wigginton and beyond!

ScaffoldingHQ has curated and vetted the Best Scaffolding Contractors near Wigginton. Find a trustworthy pro today.

Frequently Asked Questions About Scaffolding Companies

- A larger, more complex structure typically used for accessing multiple levels of a building.

- Offers greater height and versatility.

- Often used for construction, renovation, and maintenance.

- Smaller, portable platforms usually used for tasks at a single level.

- Commonly used for painting, plastering, or light repairs.

- Can be rolling or stationary.

- Project Height and Access: The height of the structure and the accessibility of the working area are primary considerations.

- Load Capacity: The weight of workers, materials, and equipment that the scaffolding needs to support.

- Project Complexity and Shape: The shape and complexity of the structure may necessitate specialized scaffolding configurations.

- Ground Conditions: The type of ground (soft, uneven, sloping) will influence the scaffolding foundation and support requirements.

- Duration of Use: The length of time the scaffolding will be needed can impact the choice of system.

- Budget: Different scaffolding types have varying costs.

- Hire Professionals: Just like erection, dismantling should be done by qualified and experienced scaffolding erectors.

- Reverse the Erection Process: The dismantling process should generally follow the reverse order of erection.

- Clear the Area: Ensure the area below is free from people and obstacles.

- Lower Materials Safely: Use ropes or other safe methods to lower dismantled components to the ground.

- Inspect Components: As components are removed, inspect them for damage and store them properly for future use.

- Steel: The most common material due to its strength, durability, and resistance to corrosion.

- Aluminum: Lighter than steel, often used for smaller projects or where weight is a concern.

- Timber: Used for decking platforms and some traditional scaffolding structures. It's less common now due to its susceptibility to rot and damage.

- Fiberglass: Used in specialized applications where electrical conductivity is a concern.

What is the difference between scaffolding and staging?

Scaffolding:

How do I choose the right type of scaffolding for my project?

How do I dismantle scaffolding safely?

What are some common materials used in scaffolding?

What is the difference between scaffolding and staging?

Scaffolding:

- A larger, more complex structure typically used for accessing multiple levels of a building.

- Offers greater height and versatility.

- Often used for construction, renovation, and maintenance.

- Smaller, portable platforms usually used for tasks at a single level.

- Commonly used for painting, plastering, or light repairs.

- Can be rolling or stationary.

How do I choose the right type of scaffolding for my project?

- Project Height and Access: The height of the structure and the accessibility of the working area are primary considerations.

- Load Capacity: The weight of workers, materials, and equipment that the scaffolding needs to support.

- Project Complexity and Shape: The shape and complexity of the structure may necessitate specialized scaffolding configurations.

- Ground Conditions: The type of ground (soft, uneven, sloping) will influence the scaffolding foundation and support requirements.

- Duration of Use: The length of time the scaffolding will be needed can impact the choice of system.

- Budget: Different scaffolding types have varying costs.

How do I dismantle scaffolding safely?

- Hire Professionals: Just like erection, dismantling should be done by qualified and experienced scaffolding erectors.

- Reverse the Erection Process: The dismantling process should generally follow the reverse order of erection.

- Clear the Area: Ensure the area below is free from people and obstacles.

- Lower Materials Safely: Use ropes or other safe methods to lower dismantled components to the ground.

- Inspect Components: As components are removed, inspect them for damage and store them properly for future use.

What are some common materials used in scaffolding?

- Steel: The most common material due to its strength, durability, and resistance to corrosion.

- Aluminum: Lighter than steel, often used for smaller projects or where weight is a concern.

- Timber: Used for decking platforms and some traditional scaffolding structures. It's less common now due to its susceptibility to rot and damage.

- Fiberglass: Used in specialized applications where electrical conductivity is a concern.