Scaffolding Companies Messingham

Find top Scaffolding Solutions in Messingham

Get up to 3 Scaffolding Companies quotes for your project today! Compare profiles, reviews, accreditations, portfolio, etc... and choose the best offer.

Apollo Scaffold Services Ltd.

York, GBApollo Scaffold Services manufacture aluminium scaffold beams and scaffold components for a wide range of applications. Our aluminium scaffold beams include the unique high capacity 1500mm X-Beam, as well as standard Ladder Beams, Lattice Beams, 750mm X-Beams, our 1300mm X-Beam and new 1300mm Super X-Beam as well as a full range of Box Beams. In addition to our range of aluminium scaffold beams, we also manufacture other scaffolding products such as Stair Treads & Public Access Steps, Ladder Access Gates, Loading Bay Gates and Temporary Roofing Systems. The Apollo Scaffold Services approach Amalgamating traditional methods with modern technology, Apollo Scaffold Services products are manufactured in Britain using only British sourced aluminium, successfully combining low weight and easy handling with high strength (copies of material test certificates are available on request). Rigorous testing, both during development and through batch testing during production, provides peace of mind that products produced by Apollo Scaffold Services are consistently manufactured to a high standard. Employing only welders coded to BS EN 287 Pt2 92AI/97 EN30042, we have established a reputation for quality, reliability, safety and customer satisfaction which has contributed to Apollo Scaffold Services products being used worldwide. Not just standard items At Apollo Scaffold Services, we pride ourselves on our ability to produce high quality work for customers who require one-offs and items for bespoke projects. Examples of this can be found on our Featured Projects page. We are approved to manufacture products to BS EN 1090 where required. If Apollo Scaffold Services can help to bring your project to reality, please get in touch. The NEW 1300mm Super X-Beam The 1300mm Super X-Beam not only offers a 12% increase in strength compared to our standard 1300mm X-Beam, but in rigorous testing it demonstrated its superiority by proving 8kN stronger in bending than its nearest competitor. Click to Learn More... In The Spotlight River Severn Eel Screen Installation In an industry first, Apollo Scaffold Services’ Lattice Beams were used to undert

- Services

- Why Us?

- Gallery

Get Quote

Caspian Group ltd

4.714 reviewsCaspian House, East Common Lane, Scunthorpe, DN16 1DE, GBCaspian Group Ltd is the UK's leading scaffold board producer, dedicated to providing top-tier scaffold boards and access solutions. Family-rooted, we pride ourselves on trust, integrity, and reliability, which define our guiding ethos. Our BSI-accredited scaffold boards ensure safety, durability, and exceptional performance. We offer a diverse portfolio of products available for both purchase and hire, catering to a wide range of project needs. At Caspian Group, we understand that your aspirations fuel our commitment to excellence, making us your ultimate scaffold partner. Our team of experts is committed to delivering exceptional customer service and exceeding your expectations. We go above and beyond to ensure your complete satisfaction.

- Services

- Why Us?

- Accreditations

- Gallery

Get Quote

Premier Access Scaffolding Ltd

546 reviewsCarlton Boulevard, Commerce House, Lincoln, LN2 4WJ, GBPremier Access Scaffolding Hire Lincolnshire is a family-run business established in 2007, providing professional scaffolding and access solutions throughout Lincolnshire. We pride ourselves on offering a friendly, stress-free, and safe solution to all our customers' scaffolding and access requirements, no matter how big or small. Our core values are built on professionalism, safety, and customer satisfaction. We strive to deliver the safest possible scaffolding service at competitive rates. Our employees undergo ongoing training in health and safety and are fully CISRS registered. All our scaffolders work to the current Scaffolding Guidance and within the 2005 Work At Height Regulations. We understand that we are guests on your premises while carrying out our work and aim to be polite, courteous, and helpful at all times. We always clean up behind ourselves and ensure minimal disruption to your home or business, leaving it as we found it. With our experienced, qualified, competent, and motivated team, we can offer safe scaffolding and access solutions throughout Lincolnshire. We offer a comprehensive range of services, including: Scaffold hire Professional scaffolders Scaffolding erection Scaffold dismantling Pro-active safety support Scaffold planning and design Scaffolding inspections Scaffolding staircases Shoring up and propping up On-site support Loading towers & rubbish chutes Mobile towers Reactive service Streetworks - Chapter 8 Regs Temporary roofs Debris netting and scaffold sheeting Confined space scaffolding IPAF operators We also operate a 24-hour out-of-hours emergency answering service. For an immediate response, call us on 01522 542244 to talk to a member of staff at any time of the day or night.

- Services

- Why Us?

- Accreditations

- Our Team

- Gallery

Get Quote

Temp Deck Scaffolding

44 reviewsYork, GBTEMP-DECK LTD is a reliable and professional scaffolding company based in Halifax. We offer a wide range of scaffolding solutions at affordable prices, catering to all your needs. Our team consists of fully trained CISRS workforce, ensuring high-quality and safe scaffolding services. We are fully insured and CISRS registered, giving you peace of mind. We pride ourselves on our efficiency and quick turnaround times. If you need scaffolding services, we're just a phone call away. We understand the importance of reliability, so we always stick to the agreed-upon time and date. Our extensive stock includes Tube & Fitting, Ringlock Systems, Adjustable Transoms Units, Hope Up Brackets, Layher Staircases and Bridges. We can provide all the scaffolding solutions you require. Contact us today for a free quote and experience the TEMP-DECK LTD difference.

- Services

- Why Us?

- Our Team

- Gallery

Get Quote

ACT Scaffolding Services LTD

ACT Scaffolding Services LTD, Barnsley, GBWelcome To ACT Scaffolding Services LTD My name is Joe Gibbons, I am the director of ACT Scaffolding Services LTD. I have worked in the scaffolding industry for over 20 years, on various types of contracts from large corporations to small businesses. I started ACT Scaffolding Services because I want to provide our customers with a service that matches my ambitions and visions. Company Objectives To provide out clients with a quality, managed service. To provide qualified, experienced, reliable and competent operatives. To provide safe working systems in line with current regulations. To deliver on time, every time, within budget. To meet customer expectations and standards. To help our employees progress and develop. To provide a working environment that is enjoyable but safe. To become a professionally respected company within the industry. Key To Success We believe that one of the main factors towards our success will be our operatives. Having the right personnel with the right skills, work ethic and attitude is essential to the growth of our business. We embrace continuous improvement. Learning new skills and coming forward with new ideas is actively encouraged, this helps our team members to be forward thinking when dealing with daily challenges, empowering them to help both the company and them succeed. This in turn provides a healthier working environment, workflow, and standard of craftmanship which we can pass on to our clients. Services Offered We provide both labour only and fully managed services. All our Scaffold Technicians are vastly experienced and qualified in all areas of the scaffolding industry. Below are just a few examples of the type of work we can undertake. Industrial Scaffold outages Experienced boiler team General scaffolding erection After use dismantling 24hr maintenance call outs Hanger/ dropper scaffold Asbestos related work Construction & Commercial Temporary roof construction Basic scaffold erection Gantry & beam work Bird cage/ cantilever Staircase System scaffold

- Services

- Why Us?

- Accreditations

- Our Team

- Gallery

Get Quote

Bostock Scaffolding Services

51 reviewsManby, Louth, The Old Grain Store, LN11 8EB, GBWhen you are in need of a scaffolder in , make Bostock Scaffolding Services your first port of call today. Whether you want to know more about what we can offer you, or want to discover more about our competitive prices, give us a call today. Since being established, the business has grown from strength to strength, ensuring a prompt and professional service, hence, we have developed an outstanding reputation within the local community. Our aim is to keep our services high and our prices very competitive.

- Services

- Why Us?

- Accreditations

- Our Team

- Testimonials

- Gallery

Get Quote

A1 Scaffolding Services Ltd

58 reviews1. Pelham Road, Holton Le Clay, DN36 5EU, GBA1 Scaffolding Services LTD is a small, reliable scaffolding company serving Lincolnshire and a 80-mile radius. Established in 2004 by managing director Gerard Wharton, who boasts 27 years of experience in the domestic, commercial, and heavy industry sectors, the company prides itself on its highly professional and well-trained team of scaffolders. These scaffolders are CIRS-CITB trained and hold passport to safety cards, ensuring they work to the highest standards. A NEBOSH CERTIFIED safety advisor is on hand to guarantee exacting standards and exceptional safety measures. A1 Scaffolding Services offers a comprehensive range of scaffolding services, including specialisation in erecting scaffolds for solar installations, re-roofing projects on both domestic and commercial properties, site work, extensions, and new builds. Competitive pricing is a key feature, and the company encourages potential clients to contact them for a FREE quote.

- Services

- Why Us?

- Our Team

- Gallery

Get Quote

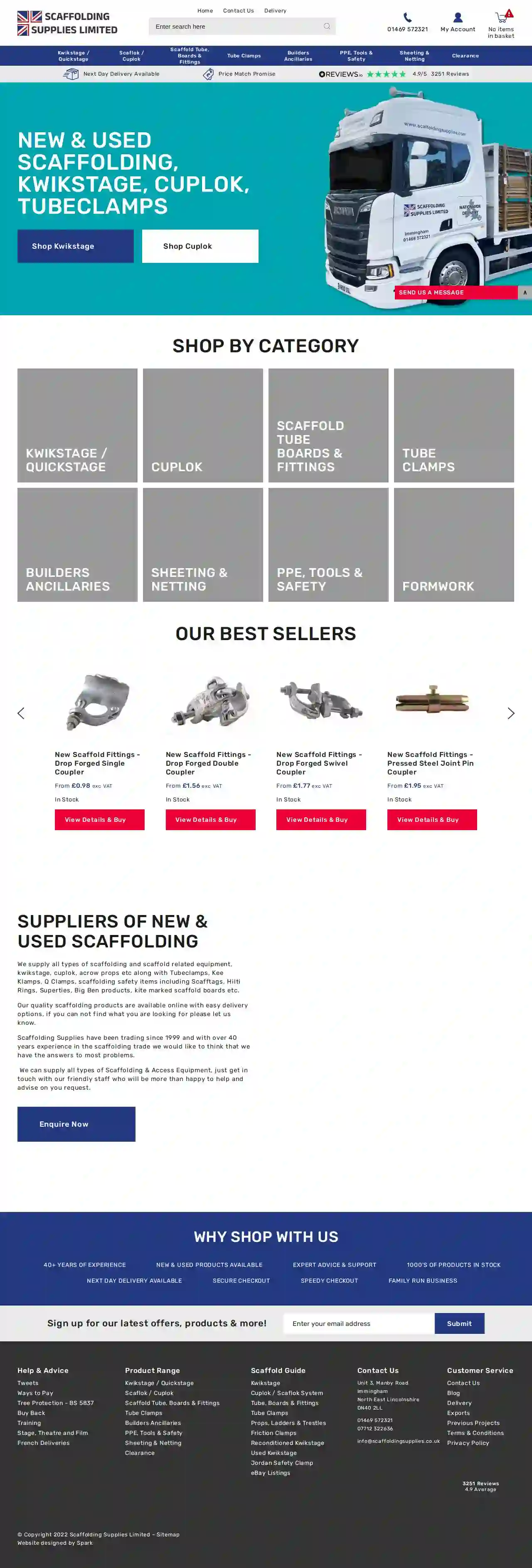

Scaffolding Supplies Limited

4.828 reviewsUnit 3, Manby Road, Immingham, DN40 2LL, GBScaffolding Supplies have been trading since 1999 and with over 40 years experience in the scaffolding trade we would like to think that we have the answers to most problems. We supply all types of Scaffolding & Access Equipment, just get in touch with our friendly staff who will be more than happy to help and advise on you request. We supply all types of scaffolding and scaffold related equipment, kwikstage, cuplok, acrow props etc along with Tubeclamps, Kee Klamps, Q Clamps, scaffolding safety items including Scafftags, Hilti Rings, Superties, Big Ben products, kite marked scaffold boards etc. Our quality scaffolding products are available online with easy delivery options, if you can not find what you are looking for please let us know.

- Services

- Why Us?

- Gallery

Get Quote

Construction Scaffolding Ltd

53 reviewsHillingdon House, Saltburn By The Sea, TS12 1LS, GBRELIABLE SCAFFOLDING COMPANY in the North East and North Yorkshire Construction Scaffolding Ltd offers a comprehensive range of scaffolding services for commercial, residential and industrial construction projects in the whole of North East and North Yorkshire. Our fully-trained team is always ready to deliver a first class service for your project. You can rely on us for Scaffolding equipment supply Scaffolding erection Work platforms Scaffolding boards and planks Scaffolding dismantling Scaffold tower hire on erected jobs Experienced We have more than 30 years of experience in erecting and dismantling scaffolding and access platforms for customers across the North East and North Yorkshire. We provide extended hire on erected jobs and we offer our services seven days a week. A complete service We provide a complete service, including erecting and dismantling the stock. Whether you need standard scaffold towers, narrow scaffold towers, double scaffold towers, access platforms or any other structures, we supply all. Please note our services are part of a package that includes erecting and dismantling the scaffolding. Fully insured When you choose Construction Scaffolding Ltd, you can rest easy in the knowledge that we are fully insured. We are also accredited by the Construction Industry Training Board (CITB). You can look forward to a quality experience.

- Services

- Why Us?

- Accreditations

- Gallery

Get Quote

S A Y Scaffolding Ltd

3.58 reviewsUnit 2-3 Rudgate, Thorp Arch, Wetherby, LS23 7AU, GBSAY Group of Companies / SAY Scaffolding (Northern) Ltd is an experienced and professional independent scaffolding company dedicated to customer service, safety, and quality in Yorkshire and The Midlands. We offer a comprehensive and efficient sub-contract package in a wide variety of areas, providing scaffolding solutions for contracts of all types and sizes, including commercial, industrial, domestic, and heritage. This has given us a proven track record in delivering innovative scaffolding solutions in a creative, cost-effective manner while remaining focused on health and safety. We believe in an honest, open-door approach, which enables us to maintain a strong working relationship with our clients based on confidence and trust - something that is reflected in the high level of repeat business we receive. Clients are welcome to visit our offices and sites by arrangement to see first hand the way we run our business. Established in 2004, SAY Group of Companies / SAY Scaffolding (Northern) Ltd has established itself as a key player within the scaffolding industry, providing access, protection, and support scaffolding for a broad range of infrastructure, building, and refurbishment projects. We are able to offer bespoke and innovative scaffolding solutions using a combination of traditional tube and fitting, and Layher system scaffolding.

- Services

- Why Us?

- Accreditations

- Testimonials

- Gallery

Get Quote

Over 4,131+ Scaffolding Businesses on our directory

Our scaffolding experts operate in Messingham and surrounding areas!

ScaffoldingHQ has curated and vetted the Best Scaffolding Contractors near Messingham. Find the most trustworthy contractor today.

Frequently Asked Questions About Scaffolding Companies

- Size and Complexity: Larger, more intricate scaffolding structures will naturally take longer to assemble.

- Scaffolding Type: System scaffolding, with its pre-engineered components, can be erected faster than traditional tube and clamp scaffolding.

- Accessibility: Difficult site access or limited working space can prolong the erection process.

- Crew Size and Experience: The number and skill level of the scaffolding erectors will impact the speed of assembly.

- Traditional and highly versatile.

- Components (tubes, clamps, boards) are assembled on-site.

- Adaptable to complex shapes and structures.

- Requires skilled labor and more time for erection.

- Pre-engineered, modular components.

- Faster and easier to erect.

- Often has higher load capacities.

- May be less versatile for complex shapes.

- Hire Professionals: Just like erection, dismantling should be done by qualified and experienced scaffolding erectors.

- Reverse the Erection Process: The dismantling process should generally follow the reverse order of erection.

- Clear the Area: Ensure the area below is free from people and obstacles.

- Lower Materials Safely: Use ropes or other safe methods to lower dismantled components to the ground.

- Inspect Components: As components are removed, inspect them for damage and store them properly for future use.

- Online Directories: Use specialized directories like ScaffoldingHQ to search for scaffolding companies in your area.

- Search Engines: Use Google or other search engines to search for 'scaffolding companies near me' or 'scaffolding rental [your location]'.

- Local Construction Associations: Contact local construction associations for recommendations.

- Word-of-Mouth Referrals: Ask friends, family, or colleagues for recommendations based on their past experiences.

How long does it take to erect scaffolding?

What is the difference between tube and clamp scaffolding and system scaffolding?

Tube and Clamp Scaffolding:

How do I dismantle scaffolding safely?

How can I find scaffolding companies near me?

How long does it take to erect scaffolding?

- Size and Complexity: Larger, more intricate scaffolding structures will naturally take longer to assemble.

- Scaffolding Type: System scaffolding, with its pre-engineered components, can be erected faster than traditional tube and clamp scaffolding.

- Accessibility: Difficult site access or limited working space can prolong the erection process.

- Crew Size and Experience: The number and skill level of the scaffolding erectors will impact the speed of assembly.

What is the difference between tube and clamp scaffolding and system scaffolding?

Tube and Clamp Scaffolding:

- Traditional and highly versatile.

- Components (tubes, clamps, boards) are assembled on-site.

- Adaptable to complex shapes and structures.

- Requires skilled labor and more time for erection.

- Pre-engineered, modular components.

- Faster and easier to erect.

- Often has higher load capacities.

- May be less versatile for complex shapes.

How do I dismantle scaffolding safely?

- Hire Professionals: Just like erection, dismantling should be done by qualified and experienced scaffolding erectors.

- Reverse the Erection Process: The dismantling process should generally follow the reverse order of erection.

- Clear the Area: Ensure the area below is free from people and obstacles.

- Lower Materials Safely: Use ropes or other safe methods to lower dismantled components to the ground.

- Inspect Components: As components are removed, inspect them for damage and store them properly for future use.

How can I find scaffolding companies near me?

- Online Directories: Use specialized directories like ScaffoldingHQ to search for scaffolding companies in your area.

- Search Engines: Use Google or other search engines to search for 'scaffolding companies near me' or 'scaffolding rental [your location]'.

- Local Construction Associations: Contact local construction associations for recommendations.

- Word-of-Mouth Referrals: Ask friends, family, or colleagues for recommendations based on their past experiences.