Commercial Scaffolding Lincoln

Find Heavy Duty Scaffolding in Lincoln

Get multiple Scaffolding for Construction Projects quotes for your project today! Compare profiles, reviews, accreditations, portfolio, etc... and choose the best deal.

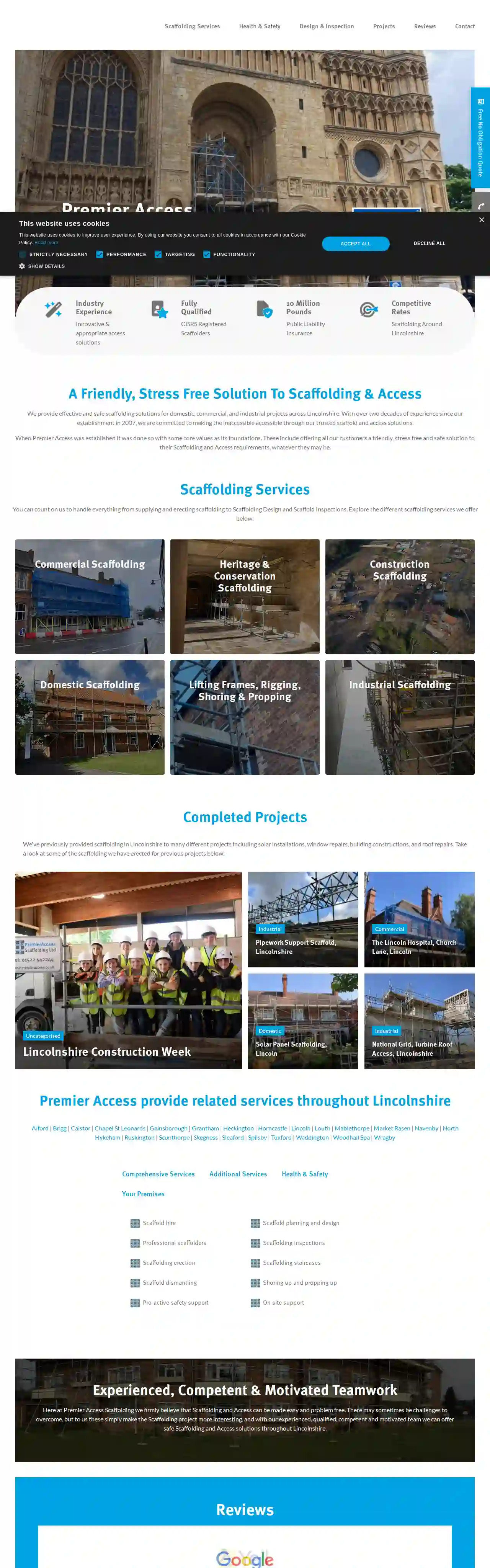

Premier Access Scaffolding Ltd

546 reviewsCarlton Boulevard, Commerce House, Lincoln, LN2 4WJ, GBPremier Access Scaffolding Hire Lincolnshire is a family-run business established in 2007, providing professional scaffolding and access solutions throughout Lincolnshire. We pride ourselves on offering a friendly, stress-free, and safe solution to all our customers' scaffolding and access requirements, no matter how big or small. Our core values are built on professionalism, safety, and customer satisfaction. We strive to deliver the safest possible scaffolding service at competitive rates. Our employees undergo ongoing training in health and safety and are fully CISRS registered. All our scaffolders work to the current Scaffolding Guidance and within the 2005 Work At Height Regulations. We understand that we are guests on your premises while carrying out our work and aim to be polite, courteous, and helpful at all times. We always clean up behind ourselves and ensure minimal disruption to your home or business, leaving it as we found it. With our experienced, qualified, competent, and motivated team, we can offer safe scaffolding and access solutions throughout Lincolnshire. We offer a comprehensive range of services, including: Scaffold hire Professional scaffolders Scaffolding erection Scaffold dismantling Pro-active safety support Scaffold planning and design Scaffolding inspections Scaffolding staircases Shoring up and propping up On-site support Loading towers & rubbish chutes Mobile towers Reactive service Streetworks - Chapter 8 Regs Temporary roofs Debris netting and scaffold sheeting Confined space scaffolding IPAF operators We also operate a 24-hour out-of-hours emergency answering service. For an immediate response, call us on 01522 542244 to talk to a member of staff at any time of the day or night.

- Services

- Why Us?

- Accreditations

- Our Team

- Gallery

Get Quote

Earls Scaffolding Ltd

53 reviewsLincoln, GBEarls Scaffolding is a well-established, family-run business with over 50 years of experience in the scaffolding industry. We pride ourselves on providing a high standard of service, safe working practices, and a tidy job. Our team of highly trained scaffolders are skilled in providing a wide range of scaffolding solutions for domestic, commercial, and industrial projects. We are committed to delivering guaranteed solutions for all project requirements, no matter how big or small. We are a medium sized business with high expectations for our men and the work they do. We believe that people are our main asset with a strong emphasis on health and safety. We have built up a first-class reputation in the industry and are proud to have a loyal client base.

- Services

- Why Us?

- Our Team

- Testimonials

- Gallery

Get Quote

Rilmac Scaffolding - Lincoln

54 reviewsCrofton Drive, Allenby Road Industrial Estate, Lincoln, LN3 4NJ, GBSince our launch in 1990 Rilmac Scaffolding has grown from a six man operation to a nationwide business, employing over 150 people, and working on many key construction projects nationwide. Rilmac Scaffolding is an access scaffolding company for construction, infrastructure, industrial, construction, housing and refurbishment across the UK. We are proud of our work in the construction sector, from commercial to retail, from education to medical, including the prestigious DNRC (Defence & National Rehabilitation Centre) for wounded service personnel. With our in house design team we regularly work with blue chip contractors on projects across the UK. Our long experience in the field of industrial scaffolding has seen us work on projects including power stations and steelworks. This has included providing access for regular maintenance, emergency access for repair during power outages, and full scale construction scaffolding for the development of new facilities. Through our access scaffolding for infrastructure projects we have been able to ensure safe and appropriate work spaces on bridges spanning both rivers and roads across the UK. Working with major contractors we have also provided stair access, public walkways, and the diversion of key utilities. Refurbishment can often present many different challenges. Road access can be restricted, existing structures may be unstable, and ongoing use of the site could be required. We are able to provide suitable solutions, such as high quality encapsulation or night working, to ensure a project runs smoothly. In dealing with damaged property, we are able to move from initial call, through design, to setting up on site within 48 hours. We provide this service for prisons, the insurance industry, facilities managers, and more. With large quantities of traditional

- Services

- Why Us?

- Accreditations

- Gallery

Get Quote

DNA Scaffolding Ltd

514 reviewsDecoy Road, Borough Fen, Moor Farm, Peterborough, PE6 7QD, GBPeterborough's chosen name for scaffolding services The team you can count on for your next development. Get a quote for your project COMMERCIAL Commercial scaffolding services DOMESTIC Domestic scaffolding services INDUSTRIAL Industrial scaffolding View more wORKING WITH YOU TO PLAN, DESIGN AND IMPLEMENT THE RIGHT SYSTEM Serving Peterborough, Cambridgeshire and Lincolnshire for over 20 years, DNA Scaffolding offers impressive value on a turn-key solution for scaffolding. Our experienced, dedicated team will be with you through the entirety of your project, from providing advice for access solutions to the site survey, design and professionally managed erection and dismantling. Working with both domestic clients and the commercial sector, we can tailor our approach to accommodate your specific needs. For larger projects we'll consult and advise on the scope of works required, and for every client, we'll schedule all aspects of the service, including attendance and clearing the site - everything you need under one roof. By building strong relationships with our clients, we provide a seamless service over the length of the contract, without any nasty surprises or hidden costs. Discuss the specifics with our team today and we'll get to work. wHERE IT ALL STARTED DNA Scaffolding was founded by Darrell Allen, a professional with over 27 years’ experience in the industry, who wished to improve the quality of scaffolding and provide a cost-effective service for commercial, industrial and domestic customers.The company has developed significantly in the past two years, guided by the operations management team working alongside Lucia Templeman (Office Manager) and Charlotte Turner (Accounts Manager). We have a collective ethos to continually improve for the benefit of both client and industry operations. With this in mind, all of our operatives are trained to a high standard and can demonstrate competency. wE BELIEVE IN KEEPING YOU SAFE Our substantial team of fully qualified CISRS and CITB registered scaffolders is NASC compliant and at your service from the beginning. Our commitment to service has ensured we’re trusted by many of the UK’s leading construction companies, local authorities, and also local and regional construction and restoration companies. In our commitment to Health and Safety on behalf of our clients and ourselves, our workforce is regularly assessed both in-house and independently to ensure the high standards you’ve a right to expect. Fully trained staff Reliable services Competitive prices whatever time of day, our 24h

- Services

- Why Us?

- Accreditations

- Our Team

- Gallery

Get Quote

Grey Wolf Scaffolding

58 reviewsPoplars Farm, Tattershall Rd, Boston, PE21 9NH, GBGrey Wolf Scaffolding is a Lincolnshire based business covering all aspects of Commercial and Domestic Scaffolding Hire in the Boston and Lincolnshire region. With over 20 years of experience, we pride ourselves in our ability to effectively communicate, action and deliver your domestic or commercial scaffolding project on time and in a safe and secure manner. Experienced, Professional and Reliable scaffolding services in Boston, Sleaford, Lincoln, Peterborough, Skegness, Grimsby, Louth, Bourne and all surrounding areas. Call for a quotation We provide an array of commercial scaffolding services including, heritage, solar, temporary roofs, propping and shoring. With this comes a wealth of experience that can be applied to any commercial environment that requires scaffolding such as new build houses, extensions, rendering and scaffolding inspections. Our wealth of knowledge and experience in the commercial and domestic scaffolding industry spans over 20+ years, making us confident that we can deliver exceptional service every time. We are committed to constantly evolving our knowledge to meet new industry trends and standards, as well as access needs. Our domestic and commercial scaffolding portfolio consists of churches, bridges, roofing and more. We can cover any needs and specific requirements. Looking for reliable, insured and experienced domestic and commercial scaffolding services in the Boston & Lincolnshire area, then look no further. Grey Wolf LTD can cater to all your requirements and scaffolding needs. Director James Brown has been working within the scaffolding industry for over 20 years and has been involved in an array of complex and advanced scaffolding projects including temporary roofs, bridges, churches, shoring, underslung and hanging scaffolds. Our ScaffoldingServices Scaffold Erection Domestic Scaffolding Services Commercial Scaffolding Services Solar Temporary roofs Propping and Shoring Newbuilds Extensions Re-Roofs

- Services

- Why Us?

- Testimonials

- Gallery

Get Quote

The Scaffold Company

4.34 reviewsToft Lodge Cottage, Stamford Road, Bourne, PE10 0JY, GBAt The Scaffold Company, we handle all aspects of access and scaffolding. With 35 years of combined experience working on high-level, railway, demolition, and factory projects, our portfolio spans both domestic and commercial sectors. Our expertise stems from hands-on experience gained with other companies, leading us to establish The Scaffold Company. We are dedicated to providing a safe, reliable, and professional service to every client, contractor, and member of the public. Our efficient and disciplined work ethic ensures a high standard of service.

- Services

- Why Us?

- Gallery

Get Quote

XL Scaffolding Ltd

4.25 reviewsLincoln, GBXL Scaffolding Ltd is a contract scaffolding company working on a variety of industrial, commercial, construction, utility and food sector projects. We work within the energy market on a number of scaffolding applications ranging from solar installations to water treatment plant upgrades. We also carry out scaffolding work to wastewater treatment works and have the required EUSR clean water trained operatives to enable us to operate within the water industry including advanced confined space training and advanced scaffold inspection. Our “Commitment to Safety” is achieved through risk management, selection of qualified and experienced labour and an ongoing training programme. XL Scaffolding Ltd uses the Scafftag handover management system to ensure all scaffolds are fit for purpose at all stages of the erect process. XL Scaffolding Ltd is a member of NASC – the No.1 national trade body for access and scaffolding in the UK. It represents over 230 leading contracting firms, scaffolding manufacturers and businesses. XL Scaffolding Ltd is an Accredited Gold Member of Constructionline – the UK’s most connected and progressive provider of procurement and supply chain management services. All of our operatives are CISRS Trained – the preferred industry-recognised scaffold training qualification in the UK. CHAS is one of the founders of third party accreditation. They are a trusted advisor and and industry-wide recognised authority on health & safety compliance. XL Scaffolding Ltd are pleased to announce that we have been granted the industry leading Alcumus SafeContractor accreditation. XL Scaffolding Ltd is registered under the Achilles Building Confidence community which connects buyers and suppliers who demonstrate compliance and improvement against leading standards of excellence in the UK Construction sector. Builder’s Profile is the open-access Common Database service providing compliance and PQQ information to the construction industry. The Code of Considerate Practice embodies the high standards the industry can and should achieve. The clear, attainable guidelines in the Code exist to help constructors make positive changes to the way they work and to operate more responsibly and respectfully. XL Scaffolding Ltd work to the NASC guidance SG4:10 and are CITB trained and CISRS health & safety compliant, all scaffolding projects are carried out after a detailed site specific risk assessment and method statement are produced. At XL Scaffolding Ltd, we value the importance of health and safety and see it as an integral part of our work. We ensure that all of our employees are trained to the highest standards and all of our works are carried out in strict accordance with all UK Health and Safety legislation and best practice requirements, including in particular the requirements of the Construction (Design and Management) Regulations 2015 and the Work at Height Regulations 2005. XL Scaffolding Ltd are members of the NASC as well as being CHAS and Safecontractor Accredited Contractors we only employ highly skilled and safety focused CISRS Registered Scaffolders. XL Scaffolding Ltd also uses the Services of Bolt On Safety Services Ltd to assist us with the fulfilment of our duties. Bolt on Safety Services Limited are Chartered Health and Safety and Chartered Environmental Advisors and provide competent, professional health and safety advice to many companies, like ours, throughout the UK. Bolt on Safety Services Limited advises and assists us in all areas of our work, ensuring that Xl Scaffolding Ltd and our clients are provided with professional advice at all times. Bolt on Safety Services Limited also regularly review and update our health and safety documentation including our extensive Health and Safety Policy and Procedures Manual, Risk Assessments and Method Statements. Bolt on Safety Services Limited also provides reliable, up-to-date information on new legislation and accident prevention, as well as a 24 hour support line to our key staff. To ensure customers and installers are not put at risk, all staff are trained in the relevant safe systems of work and procedures, including CDM, Safe Work at Height, Asbestos Awareness and a variety of other subjects. We carry out regular on site safety briefings and all staff are provided with and are required to wear the appropriate Personal Protective Equipment (PPE). In addition to this XL Scaffolding Ltd is covered by a full and comprehensive public liability insurance policy, whilst detailed risk assessment and method statements are prepared for each of our projects. XL Scaffolding Ltd has its premises in Peterborough and is involved in supplying scaffolding services to the food, construction, civil engineering and manufacturing industries throughout the whole of the UK. We are fully committed to safety and best practices within the scaffolding sector, and we ensure our new employees share this goal. We recruit motivated and dynamic team members that hold the necessary scaffolding Industry tickets and offer competitive salaries in return. XL Scaffolding is committed to ongoing training programmes for our staff not only to keep up with changing legislation but to equip our employees with the necessary Certificates and qualifications to be able to work safely within this industry. Examples of such training include, but are not limited to, Confined Space Training – IPAF certification – SSSTS and SMSTS (for our Supervisors and Managers)- First Aid and Harness Suspension Rescue. XL Scaffolding Ltd is committed to the development of enthusiastic and reliable apprentices and ensures that they travel safely from novice right through to Part 2/Advanced Ticket holder status using CITB (and other Industry/Government approved) training centres and by way of giving them on site experience.

- Services

- Why Us?

- Accreditations

- Gallery

Get Quote

Castlebuild Scaffolding Ltd

4.84 reviewsSpalding, Lincolnshire, Holbeach Road, PE12 6JP, GBCastlebuild Scaffolding Ltd is a main supplier of Scaffold Access and Support Systems in the specialized Petro-Chemical and Food Industries as well as various Domestic and Industrial Contracts. With over 25 years of experience, we have earned an excellent reputation for providing high-quality services and solutions. Our team is CITB registered, CISRS qualified, and trained in TG20:13 and SG4:15, ensuring that all our projects are completed to the highest standards. We have been shortlisted for 'Supplier of the Year' at the Greater Lincolnshire Construction and Property Awards 2022. Our commitment to health and safety is paramount, and we regularly conduct audits, training, and toolbox talks to ensure we maintain the highest standards.

- Services

- Why Us?

- Accreditations

- Our Team

- Gallery

Get Quote

LLJ Scaffolding Services LTD

53 reviewsLincoln, GBLLJ Scaffolding take pride in all their clients commercial, industrial and domestic scaffolding projects. Lee and Jack formed LLJ Scaffolding Services LTD in 2019 after being in the scaffolding industry for over a decade. Being eager to deliver a high quality standard of service, providing safe access solutions and building strong working relations with their clients has resulted in high volumes of repeat custom. Look no further for a local, reliable, and experienced scaffolding company based in Boston, Lincolnshire.

- Services

- Why Us?

- Gallery

Get Quote

Silverline Scaffolding

53 reviews30 Queens Street, Horncastle, LN9 6BD, GBSilverline Scaffolding is a professional, reliable, and fully accredited company operating in Lincolnshire and the wider area. With over 20 years of experience in the Scaffolding trade, we pride ourselves on providing a comprehensive and expert Scaffolding service. From the planning stage to the finished article, we are with you every step of the way, ensuring that you are completely satisfied with the end result. We believe in offering a professional yet personal service for each job. Our mission is to provide residents of Lincolnshire with a hassle-free Scaffolding service where all work exceeds expectations, meets deadlines, and offers excellent value. We strive to be a Scaffolding company you can always rely on, renowned for both high-quality work and excellent value for money. Customer satisfaction is paramount to us, and we are committed to building long-lasting relationships with our clients.

- Services

- Why Us?

- Accreditations

- Gallery

Get Quote

Over 1,961+ Scaffolding Businesses on our directory

Our scaffolding pros operate in Lincoln & beyond!

ScaffoldingHQ has curated and vetted Top Scaffolding Companies in Lincoln. Find a top & reliable contractor today.

Frequently Asked Questions About Commercial Scaffolding

- Experience: Look for a company with extensive experience in commercial scaffolding projects similar in scope and complexity to yours.

- Reputation: Check online reviews and testimonials to gauge their reliability, quality of work, and professionalism.

- Safety Record: Inquire about their safety protocols, training programs, and accident history.

- Licensing and Insurance: Verify they are fully licensed, insured, and bonded to protect you from liability.

- Capacity and Equipment: Ensure they have the resources, equipment, and expertise to handle your project's size and specifications.

- Pricing and Contracts: Obtain detailed quotes, compare pricing, and review contract terms carefully.

- Communication and Project Management: Choose a company that communicates clearly, is responsive to your needs, and has a well-defined project management process.

- Falls from Height: The most significant risk, often due to inadequate guardrails, improper harness use, or unstable platforms.

- Falling Objects: Tools, materials, or debris falling from the scaffolding can injure workers below.

- Scaffold Collapse: Improper erection, overloading, or inadequate foundation support can cause a collapse.

- Electrocution: Contact with overhead power lines is a severe hazard, especially for taller scaffolding structures.

- Weather Conditions: High winds, rain, snow, or ice can make scaffolding unstable and hazardous.

- Unsafe Access: Improperly secured or damaged ladders or stairs can lead to falls.

- Lack of Training: Workers without adequate scaffolding safety training are at higher risk of accidents.

- Use ScaffoldingHQ: Submit your project details on our platform to receive quotes from multiple pre-vetted scaffolding companies in your area.

- Contact Companies Directly: Find commercial scaffolding companies in your area (through online searches or referrals) and reach out to them directly for quotes.

- Planning and Coordination: Working with contractors and the scaffolding company to plan the scaffolding erection, ensuring it meets project requirements and complies with regulations.

- Overseeing Erection and Dismantling: Supervising the scaffolding erectors to ensure the structure is built and dismantled safely and correctly.

- Safety Inspections: Conducting regular inspections of the scaffolding to identify and address potential hazards.

- Enforcing Safety Procedures: Ensuring workers on the scaffolding are following safety protocols, wearing appropriate PPE, and working safely.

- Managing Scaffolding Tags: Ensuring scaffolding tags are up-to-date and accurately reflect the inspection status.

- Emergency Response: Responding to any scaffolding-related incidents or emergencies.

How do I choose the right commercial scaffolding company?

What are some common hazards associated with commercial scaffolding?

How can I get a quote for commercial scaffolding?

What is the role of a scaffolding supervisor?

How do I choose the right commercial scaffolding company?

- Experience: Look for a company with extensive experience in commercial scaffolding projects similar in scope and complexity to yours.

- Reputation: Check online reviews and testimonials to gauge their reliability, quality of work, and professionalism.

- Safety Record: Inquire about their safety protocols, training programs, and accident history.

- Licensing and Insurance: Verify they are fully licensed, insured, and bonded to protect you from liability.

- Capacity and Equipment: Ensure they have the resources, equipment, and expertise to handle your project's size and specifications.

- Pricing and Contracts: Obtain detailed quotes, compare pricing, and review contract terms carefully.

- Communication and Project Management: Choose a company that communicates clearly, is responsive to your needs, and has a well-defined project management process.

What are some common hazards associated with commercial scaffolding?

- Falls from Height: The most significant risk, often due to inadequate guardrails, improper harness use, or unstable platforms.

- Falling Objects: Tools, materials, or debris falling from the scaffolding can injure workers below.

- Scaffold Collapse: Improper erection, overloading, or inadequate foundation support can cause a collapse.

- Electrocution: Contact with overhead power lines is a severe hazard, especially for taller scaffolding structures.

- Weather Conditions: High winds, rain, snow, or ice can make scaffolding unstable and hazardous.

- Unsafe Access: Improperly secured or damaged ladders or stairs can lead to falls.

- Lack of Training: Workers without adequate scaffolding safety training are at higher risk of accidents.

How can I get a quote for commercial scaffolding?

- Use ScaffoldingHQ: Submit your project details on our platform to receive quotes from multiple pre-vetted scaffolding companies in your area.

- Contact Companies Directly: Find commercial scaffolding companies in your area (through online searches or referrals) and reach out to them directly for quotes.

What is the role of a scaffolding supervisor?

- Planning and Coordination: Working with contractors and the scaffolding company to plan the scaffolding erection, ensuring it meets project requirements and complies with regulations.

- Overseeing Erection and Dismantling: Supervising the scaffolding erectors to ensure the structure is built and dismantled safely and correctly.

- Safety Inspections: Conducting regular inspections of the scaffolding to identify and address potential hazards.

- Enforcing Safety Procedures: Ensuring workers on the scaffolding are following safety protocols, wearing appropriate PPE, and working safely.

- Managing Scaffolding Tags: Ensuring scaffolding tags are up-to-date and accurately reflect the inspection status.

- Emergency Response: Responding to any scaffolding-related incidents or emergencies.